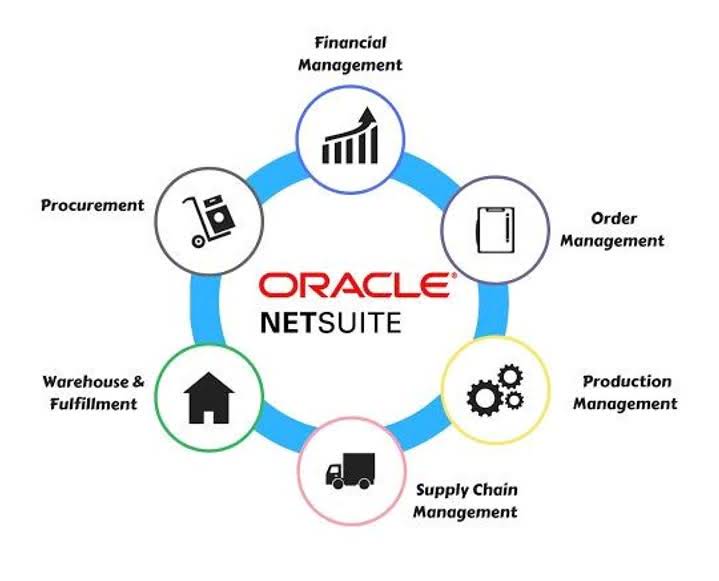

Some industries, such as metal fabrication, have multiple processes that are closely related and share many common resources. Management teams can then use this information when deciding where new production lines should be established, or existing ones expanded to maximize productivity levels across all facilities that produce similar items. For example, if you need to wait for a shipment of parts from overseas, this could lead to delays in manufacturing. The standards, rules, guidelines, and industry-specific requirements for financial reporting. ProjectManager is award-winning work and project management software that connects teams with collaboration tools and a single source of truth. With features for task and resource management, workload and timesheets, our flexible software can meet the needs of myriad industries.

Account

These are indirect materials, indirect labor, indirect expenses and other chargeable items. While these costs may seem small, they can add up quickly and eat into your profits. That’s why it’s important to carefully track and manage your manufacturing overhead costs. Determining the manufacturing overhead expenses can also help you create a budget for manufacturing overhead. Companies must be able to respond quickly to changing market conditions to maintain profitability. If a company cannot rapidly adjust its manufacturing overhead costs, it may face serious financial problems.

Definition of Factory Overheads

- Regular maintenance schedules can help, but unforeseen issues can still arise.

- Manufacturing overhead is also known as factory overhead, production overhead, and factory burden.

- Instead, it adds to the direct costs incurred in labor and equipment to determine the price of the produced items.

- This account is a non-operating or “other” expense for the cost of borrowed money or other credit.

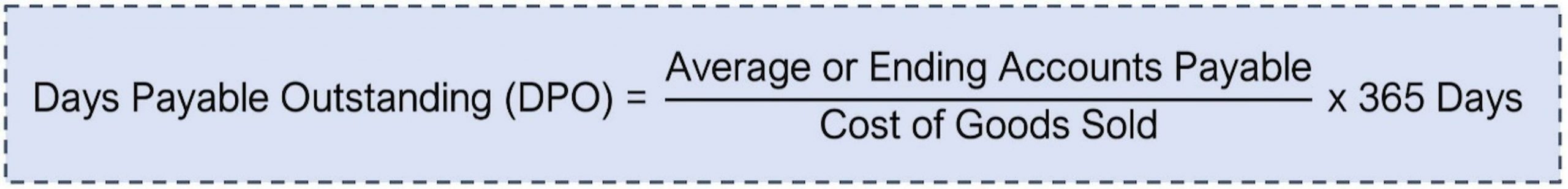

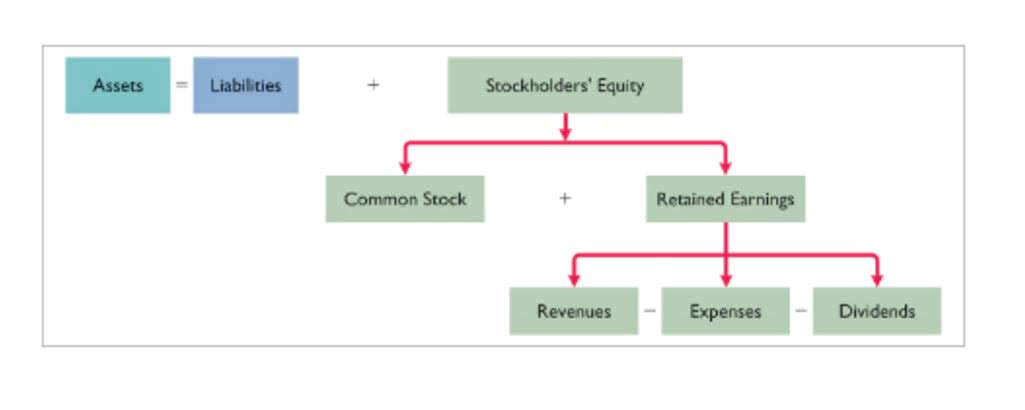

Since their usage isn’t constant, they’re included as variable overhead costs. Accountants calculate this cost for the whole facility, and allocate it over the entire product inventory. Generally Accepted Accounting Principles (GAAP) indicate that manufacturing overhead should be added to the cost of direct materials and labor when determining the Cost of Goods Sold (COGS) and the inventory value. Therefore, each of these figures must be reported on both the balance sheet and income statement. In addition to determining the cost of goods sold, manufacturing overhead helps companies manage their spending. It’s easy to make the mistake of focusing only on the direct manufacturing costs like materials and labor.

Calculate the Overhead Absorption Rate

- Absorption costing accounting practices will then attribute the overhead charges to products, regardless of whether they’ve sold.

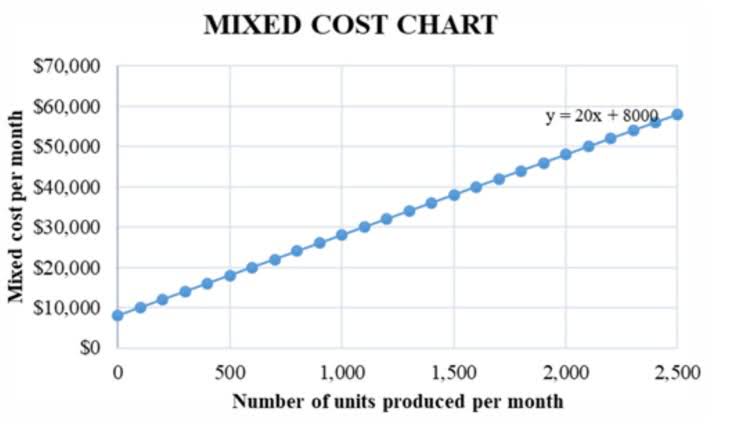

- You can also use the formula below to calculate a predetermined manufacturing overhead cost rate that will be allocated to all the units that are produced instead of allocating overhead costs to each of them.

- This includes depreciation on the buildings used in the production operation, assuming those buildings are owned by the company.

- Knowing the overall manufacturing overhead is all that’s needed to keep the books balanced.

- This adherence not only builds investor confidence but also provides a solid foundation for strategic decision-making.

However, if the company produces more units of the better-selling product than it should, it will incur additional costs. Allocating overhead manufacturing costs to products can help managers avoid these mistakes. It is easy to overlook manufacturing overhead when planning your budget and forecasting sales, but it is an integral part of your business. When you include manufacturing overhead in your financial projections, you will be more likely to accurately predict how much money you will need each month. If you’re a business owner, you know that your overhead expenses are the costs of running a business that isn’t directly related to making or selling a product.

Another advantage of departmentalizing manufacturing overhead is that it makes it easier for companies to track their costs over time. This helps them determine whether or not they’re getting good value for their money or if cheaper alternatives might be available elsewhere. Departmentalization of Overheads is a procedure that helps allocate overhead expenses to a particular cost center/ department/ account. It helps determine production’s actual cost and helps make decisions regarding a pricing policy, costing, and financial control.

This can include security guards, janitors, those who repair machinery, plant managers, supervisors and quality inspectors. Companies discover these indirect labor costs by identifying and assigning costs to overhead activities and assigning those costs to the product. That means tracking the time spent on those employees working, but not directly involved in manufacturing. Understanding the calculation of your overhead manufacturing costs plays a critical role in tracking your financial books accurately.

- They can accomplish this by purchasing new machinery or retrofitting old machines with the latest technology.

- Supervisors who oversee specific aspects of the manufacturing process are considered indirect labor, and thus are counted as part of manufacturing overhead.

- Understanding the calculation of your overhead manufacturing costs plays a critical role in tracking your financial books accurately.

- The quality of goods produced also affects manufacturing overhead because it increases or decreases the amount spent on direct materials, direct labor, and factory overhead.

- It’s added to the cost of the final product, along with direct material and direct labor costs.

Manufacturing overhead refers to indirect costs a company or manufacturer incurs during production. These manufacturing overhead costs are called indirect costs because it’s hard to trace them to each product. By following these steps, businesses can accurately assign manufacturing overhead costs to their products, ensuring a precise understanding of production expenses. This method helps not only with better budgeting and cost control but also with setting competitive pricing strategies. Now that you have an estimate for your manufacturing overhead costs, the next step is to determine the manufacturing overhead rate using the equation above. Most https://www.pinterest.com/kyliebertucci/stampin-up-business-tips/ manufacturing overhead budgets cover a year, but each of these values are calculated quarterly.